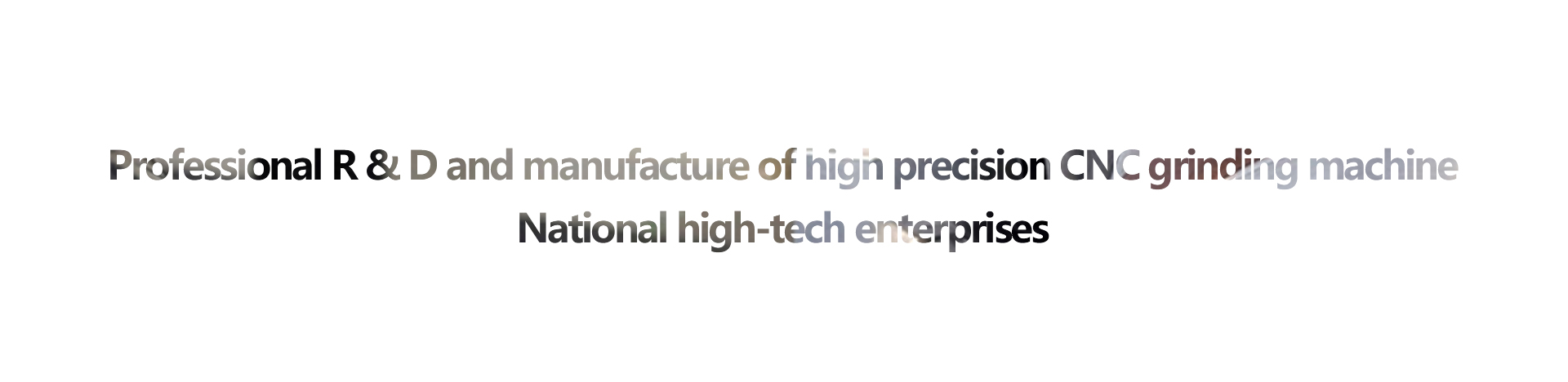

Product structure function:

1. Mechanical structure:

1) The main movement of the vertical grinder includes the rotary movement of the rotary table spindle, the left and right lateral movement of the sliding saddle (X1/X2 axis), and the upper and lower longitudinal movement of the grinding wheel ram (Z1/Z2 axis).

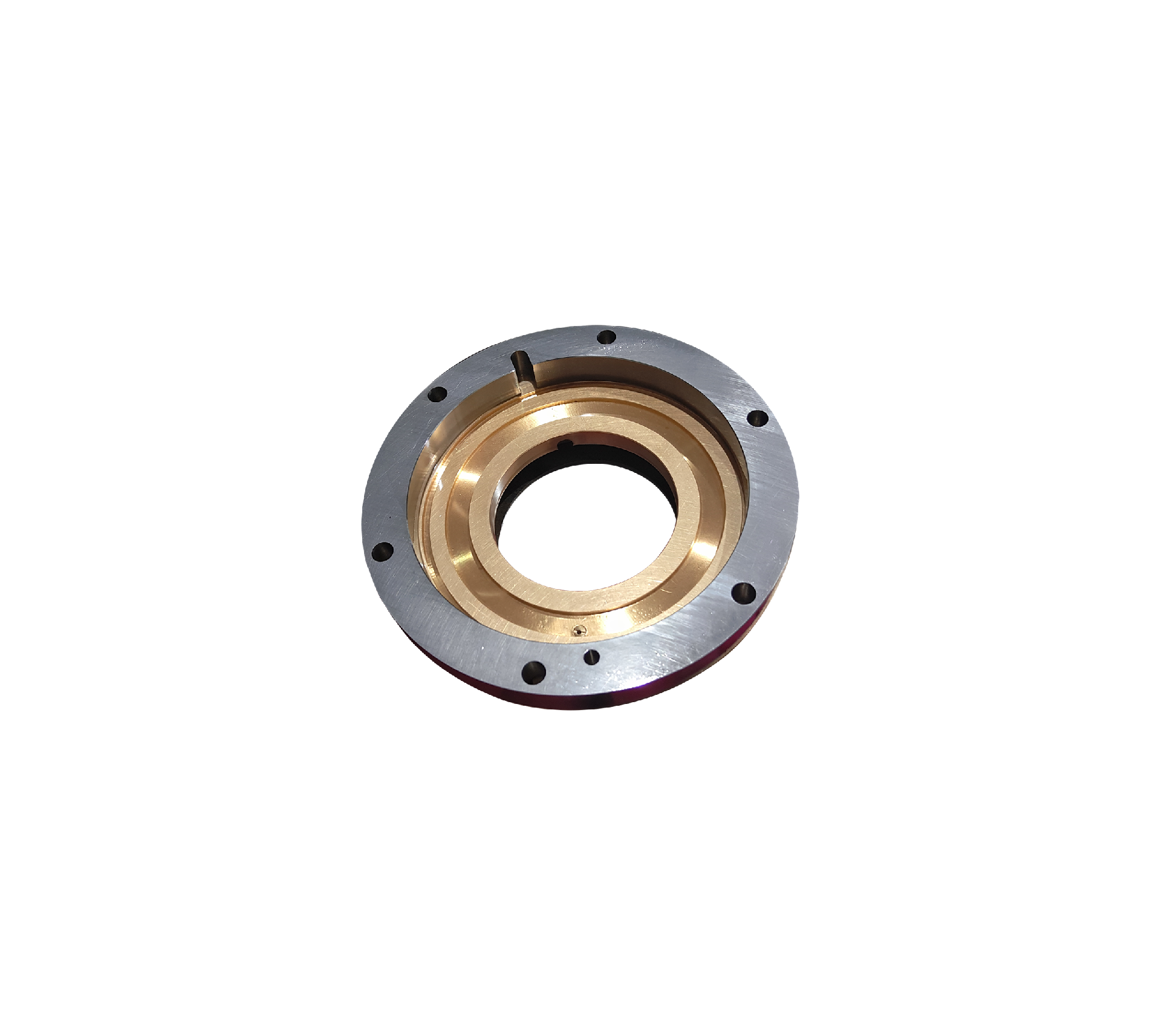

2) The grinding wheel spindle of the machine is arranged with vertical two axes: one axis is responsible for the processing of the outer circle of the parts; The other shaft is responsible for grinding the inner circle (inner ring) of the part.

3) The bed is a gantry integrated structure, HT300 cast iron material, after two high temperature thermal aging treatment, can maintain long-term stability, no deformation.

4) Excellent rigidity gantry grinding platform, two-axis grinding wheel structure, can achieve a part clamping, coarse, fine grinding or multiple processes to complete, to ensure that the tolerance of parts better than the use of requirements.

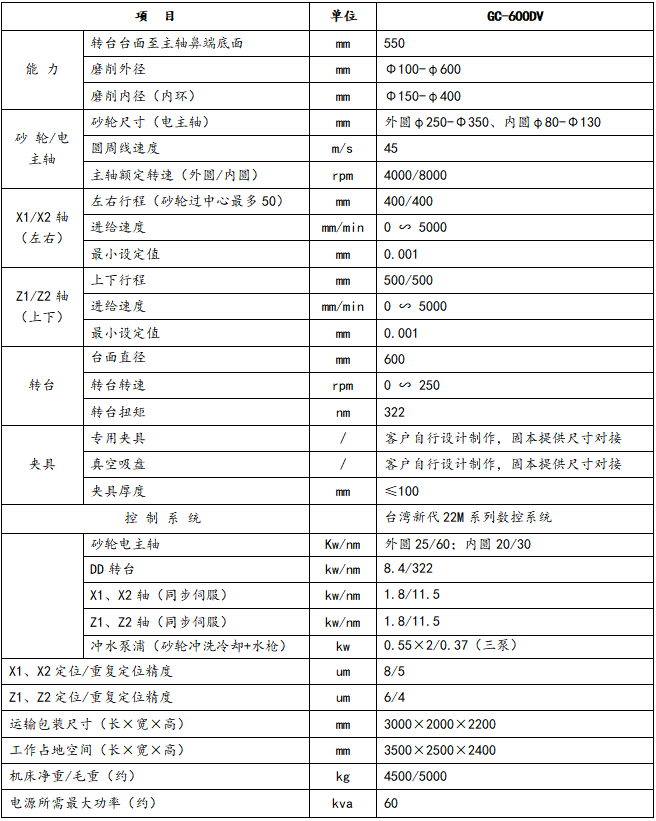

5) The X1/X2/Z1/Z2 axis uses high-precision machine tools special, ultra-rigid SRG roller rail, as well as high-precision, small lead ball screw, through the laser test correction accuracy, with smooth operation, rapid response, accurate positioning characteristics.

6) The X and Z axes are driven by "servo motor + double diaphragm no-backlash coupling + ball screw", and the four-axis feed accuracy and back backlash are compensated by laser inspection to meet the needs of micro-feed.

7) The machine tool lubrication system adopts fixed-point and quantitative oil supply mode. The lubricating oil box is equipped with pressure and liquid level detection, and the system alarm prompts to ensure that the linear guide rail and ball screw of the machine tool do not lose oil.

8) The machine can be configured with special fixtures (such as: vacuum sucker module needs to be prepared by customers), with convenient clamping, flexible adjustment, safe operation characteristics, strong adaptability to parts specifications.

9) Grinding wheel automatic dressing: with electric diamond grinding wheel dresser; Automatic grinding wheel dressing according to process requirements.