Product Details

Excellent features of cylindrical grinding machine:

High precision, high speed, easy to operate:

Modular, high-rigidity bed and spindle structure, with high-power, high-inertia servo motor;

High precision CNC control system, high precision servo + ball screw +HEIDENHAI grating rule no gap transmission;

Manual precision scraping V-V sliding guide rail, Turcite B wear plate + intensive lubrication oil groove, dynamic pressure effect is stable;

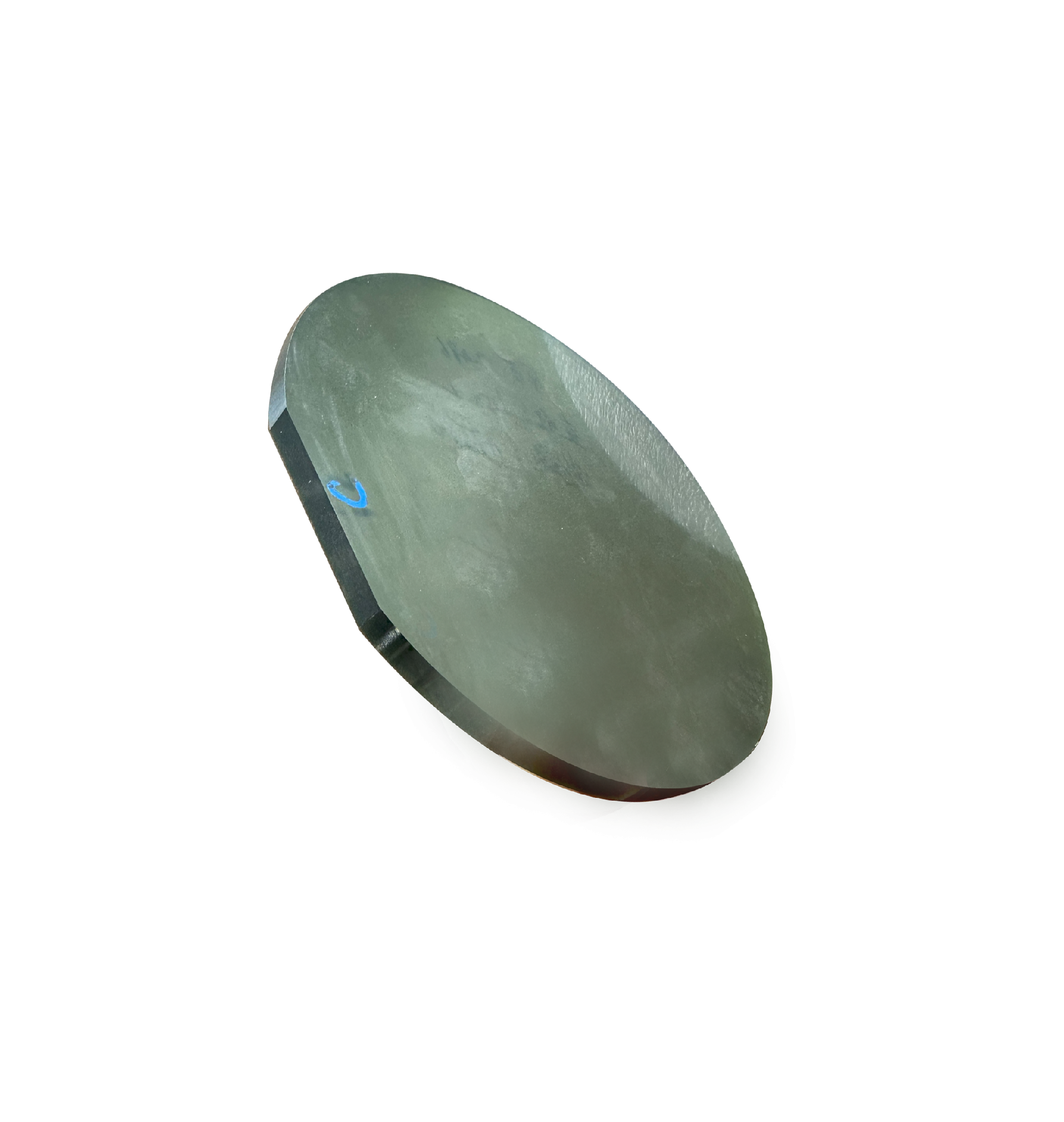

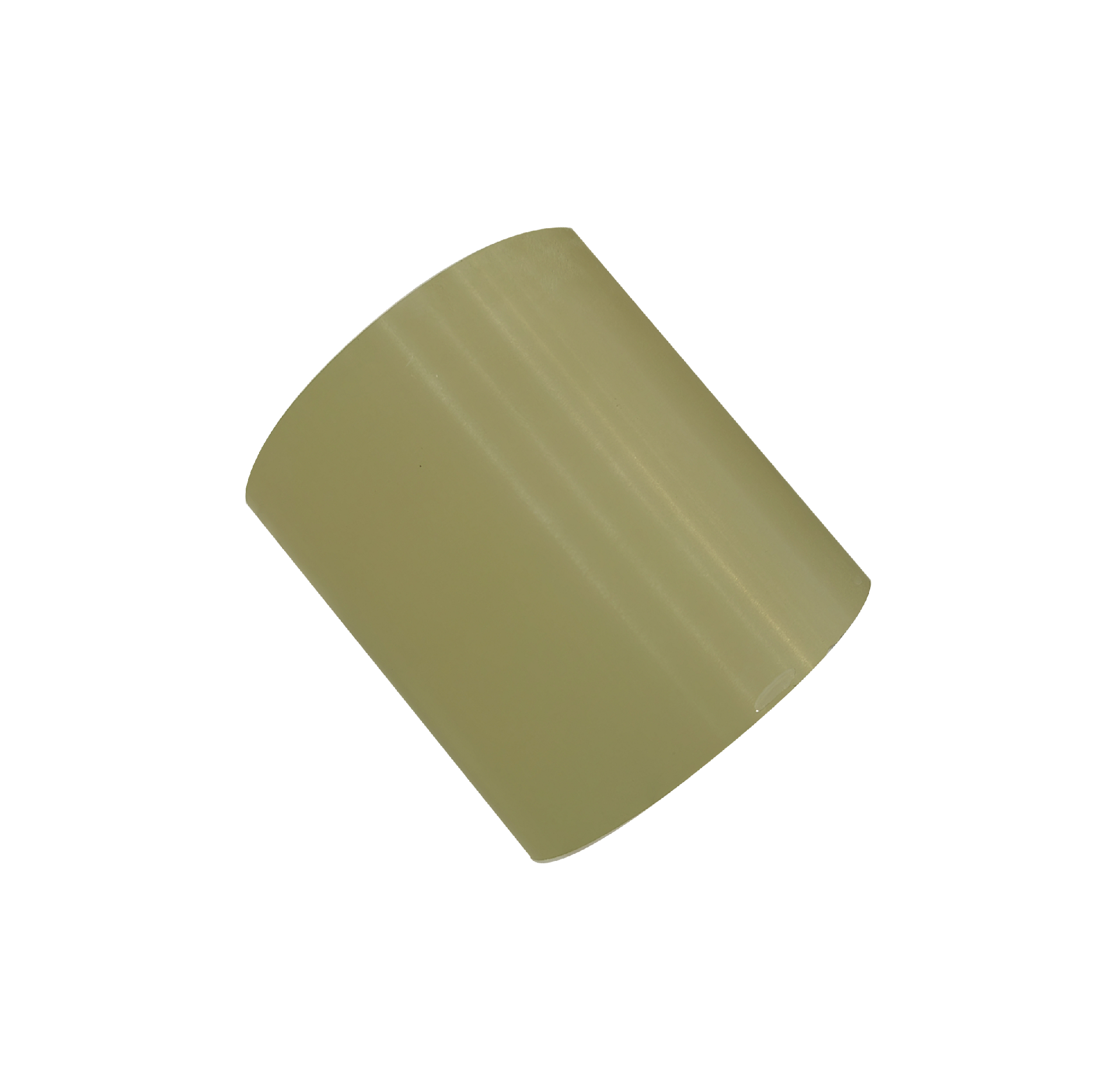

Micron-level ultra-precision feed to meet the needs of mirror and non-circular curved surface grinding;

Man-machine operation screen, easy to achieve automatic grinding, automatic speed change, automatic dressing and automatic compensation;

Multiple machines and assembly line layout, low labor cost; High stability and long life effect.

specificity

dimension

● Distance: 500/750 kg

● Center height: 125 mm

● Large workpiece weight: 80/100/150kg

hardware

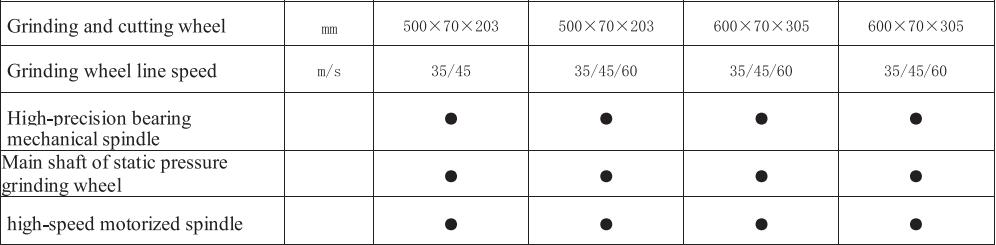

● Optional grinding wheel spindle:

● Non-contact static and dynamic grinding wheel spindle with high rigidity and low temperature rise;

● Mechanical spindle equipped with high-precision angular contact rolling bearings;

● CBN is suitable for high speed grinding of electric spindle.

software

● Using icon programming operation, friendly interface, easier to learn programming;

● The quick setting function greatly reduces the time for machine tool adjustment and resetting;

● Standardized interface for peripheral devices.

Configuration features:

● Platform modular grinding wheel holder with interchangeable grinding spindle

● Optional inverter;

● Optional grinding mode with constant speed limit;

● Cylindrical grinding wheel diameter is 500/600mm;

● CBN grinding wheel suitable for high-speed grinding can be selected.

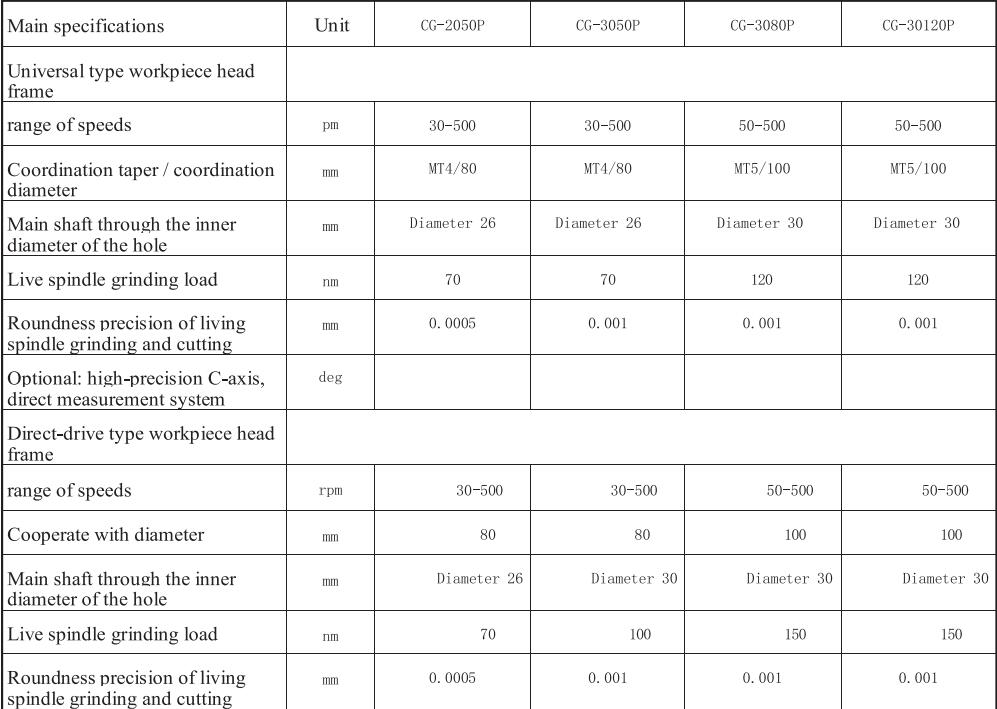

● Standard configuration type workpiece head holder, allowing the installation of chuck, expand the grinding range of the machine;

● Optional C-axis function of the workpiece head holder, can provide non-circular line parts of high-precision machining;

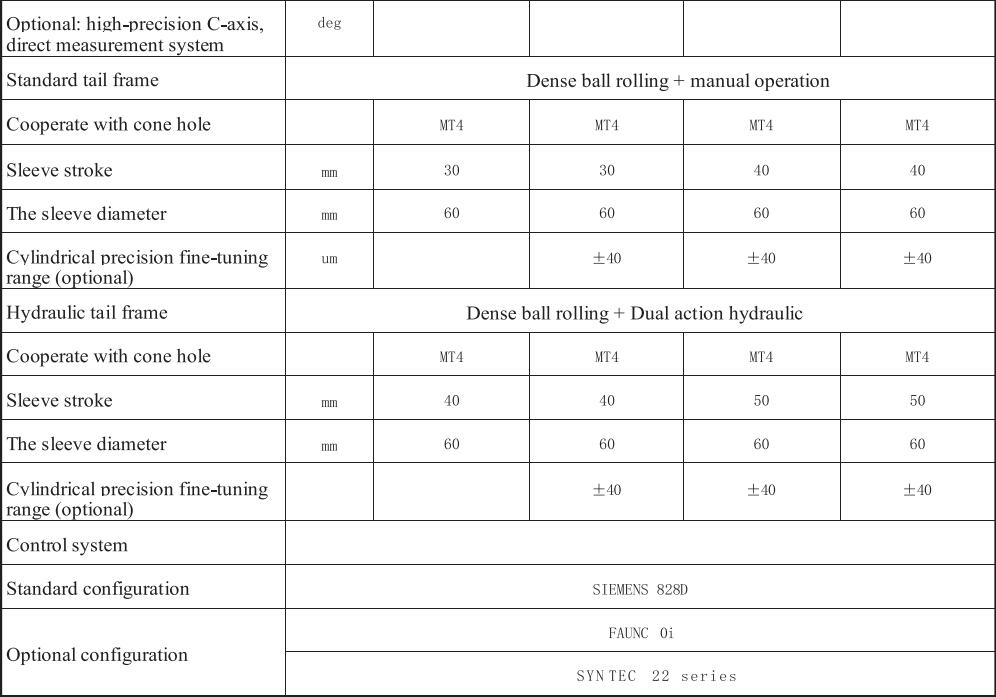

● Tailframe with dense ball bearings as standard;

● Tailstock with taper trimming function is optional.

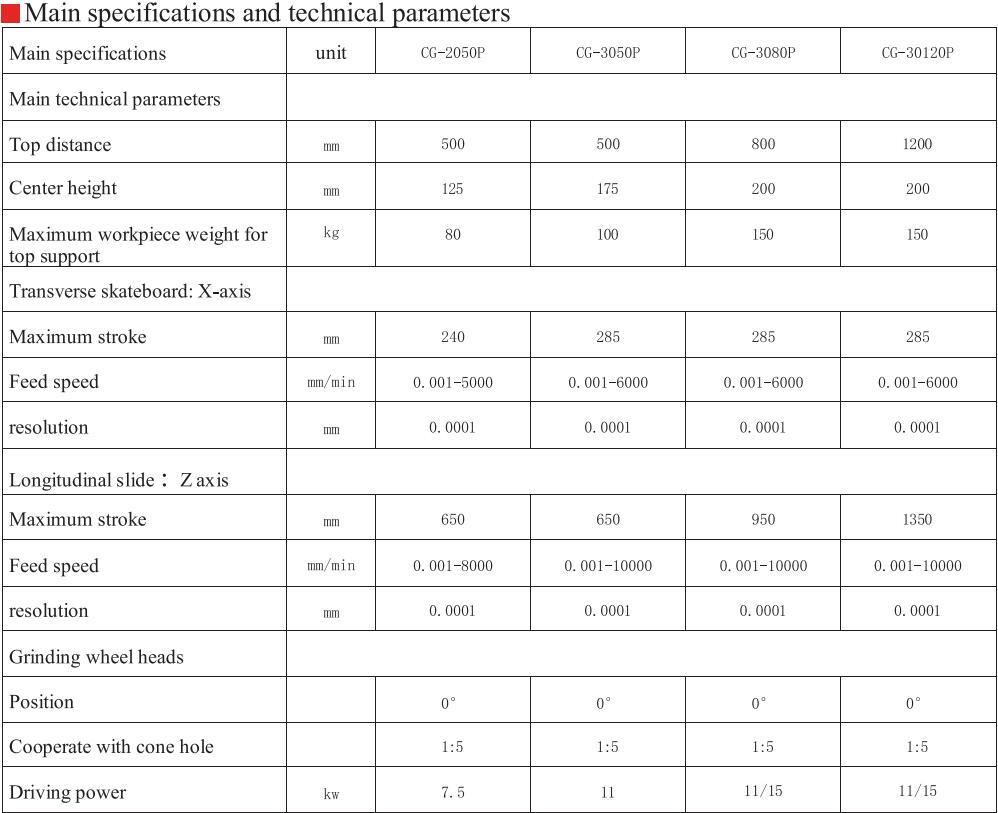

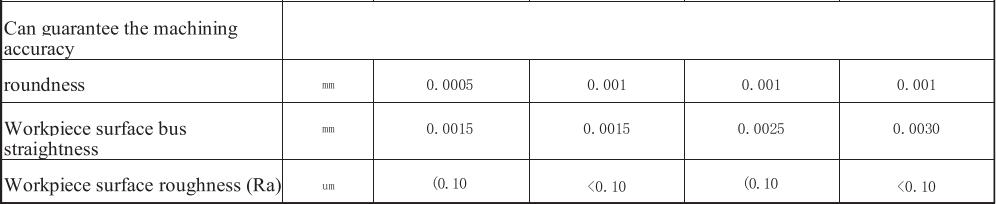

Main specification parameter table